Peripheral equipment

- Bottle extractor: The SR includes an automatic ejection system, which sucks out the blown container, as the mold opens, and transports it on the automatic neck-trimming unit.

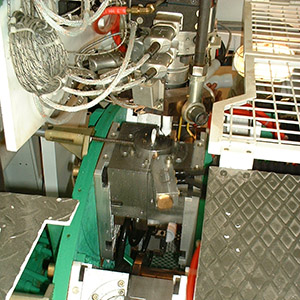

- Neck trimming unit: After positioning on the neck-trimming unit the blown containers are conveyed to a single disk rotary neck trimming which cuts off the neck-scrap. The finished items and the neck-scraps are automatically separated for their respecting conveying(option). The neck-trimming unit can be adjusted to suit any item height and neck types (ring neck, screw neck, etc.).

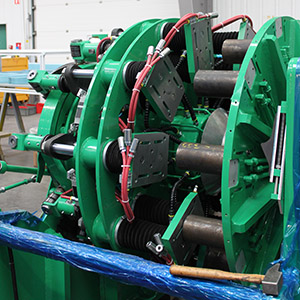

- Crushing machine: The machine can recycle the tail-scraps, neck-scraps and parisons, after being ground.

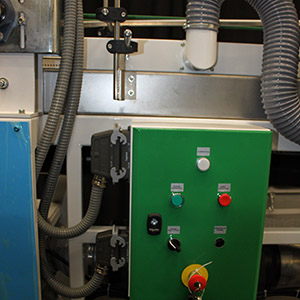

- Feeding Unit - Dosing Unit: A system can be fitted to allow filling of the extruder with mixing of virgin raw material, recycled and coloring.