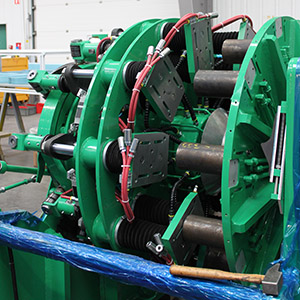

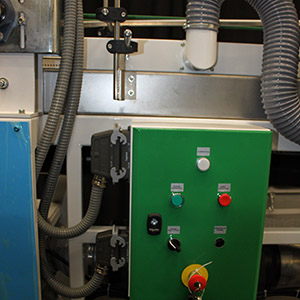

The blowing unit

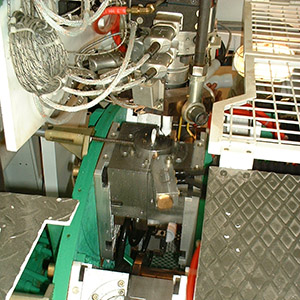

The SR machine has molds fitted on a rotary blow-molder with a horizontal shaft. This rotary unit, driven by an electric speed variator and motor-reducer, includes two circular plates set in a vertical position: one holds the fixed mold-halves, the other one the sliding units bearing the mobile mold-halves. Compressed air and mold cooling water are supplied through the central shaft. The molds made of stainless steel can be easily dismounted. A double guiding cam, to provide a smooth and silent mold closing, mechanically controls the opening and closing of the molds. Compressing steel spring washers performs mold locking. Each mold travels in turn under the die and catches a section of parison cut by a pneumatically actuated tube-cutter. The items are blown by a sliding needle, supplied with compressed air and fastened to the upper part of each mold is equipped with grooved jaws to remove the base tail-scrap, which can be automatically removed from the machine. The machine includes an automatic parison recovery system allowing machine start-up without any manual action in the machine and therefore with the door closed (safety). The collected parisons are automatically removed.