Options

Only available on models SR6, SR8 and SR10:

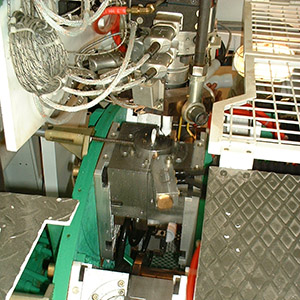

Parison control

The SR machine can be equipped with a parison control head. This equipment allows to control the thickness of the side of the containers. This system is controlled by a hydraulic servo cylinder. The use of parison control enables to optimize the bottles weight which permits a reducing of this weight and thus, savings.

Coextrusion

The SR machine is designed to receive a kit of coextrusion. This one consists of an additional extrusion machine, a changer of sieve and a specific head of extrusion. This additional extrusion machine enables to treat the aggregates of crushing colored in black. The changer of sieve enables to recover the impurities of crushing. This unit thus made up allows to carry out a multi-layer parison W/B/W: two external layers made out of virgin and clean raw material colored in white, and a black internal layer being used as a barrier to UV.

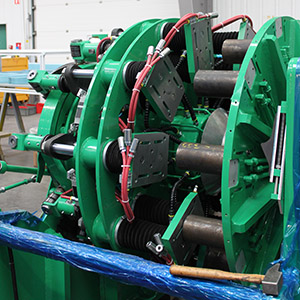

Transport of the articles and wastes:

The SR machine can also be equipped with conveying systems of items to silo(s) or scraps to the crushing machine.